Gloss & Appearance

Orange Peel

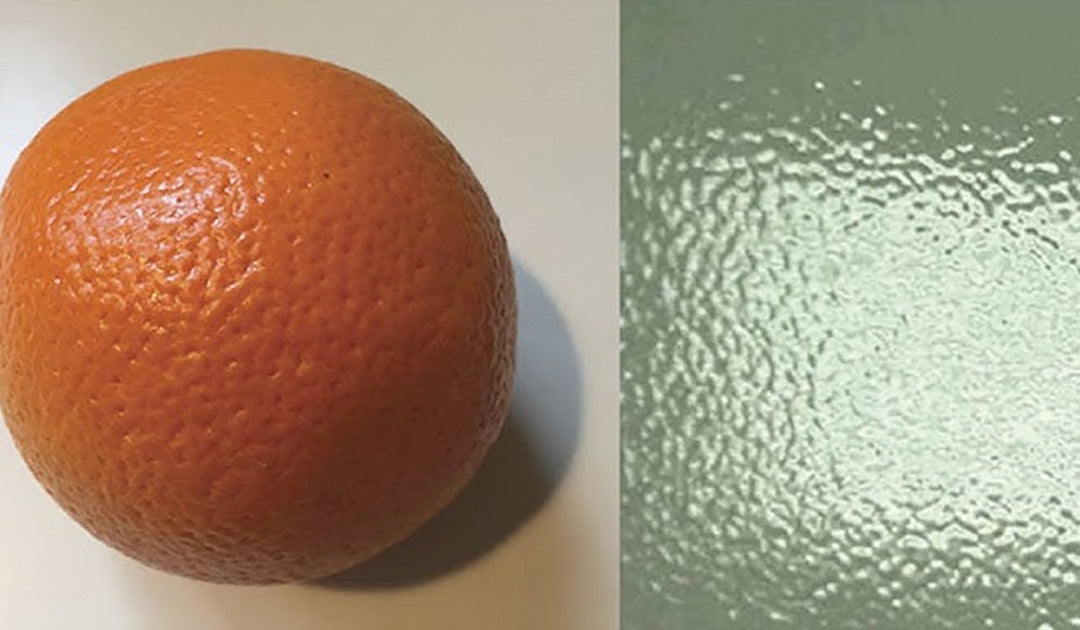

A description of the smoothness of the coating. Where coatings are not totally level they develop a waviness in the coating, not dissimilar to an orange peel.

Orange Peel

Short or long waviness of powder coating, noticeable only after curing.