Gloss & Appearance

Haziness

Similar to 'Sheen', haziness is more correct termed the 'Definition of Image' of a coating and is a measure of the clarity of the reflection, or 'mirror-like' finish of the coating. This attribute is usually confined to gloss coatings.

Pre-Cure

Appearance looks uneven and broken before curing.

-

Potential Cause

Back ionisation occurring. Where voltage is too high, or where the gun nozzle is too close to the part the powder layer reaches a saturation point, beyond which additional coating is deflected off the surface and eventually causing the deposited film to jump off the part, creating craters and star-like patterns in the powder film.

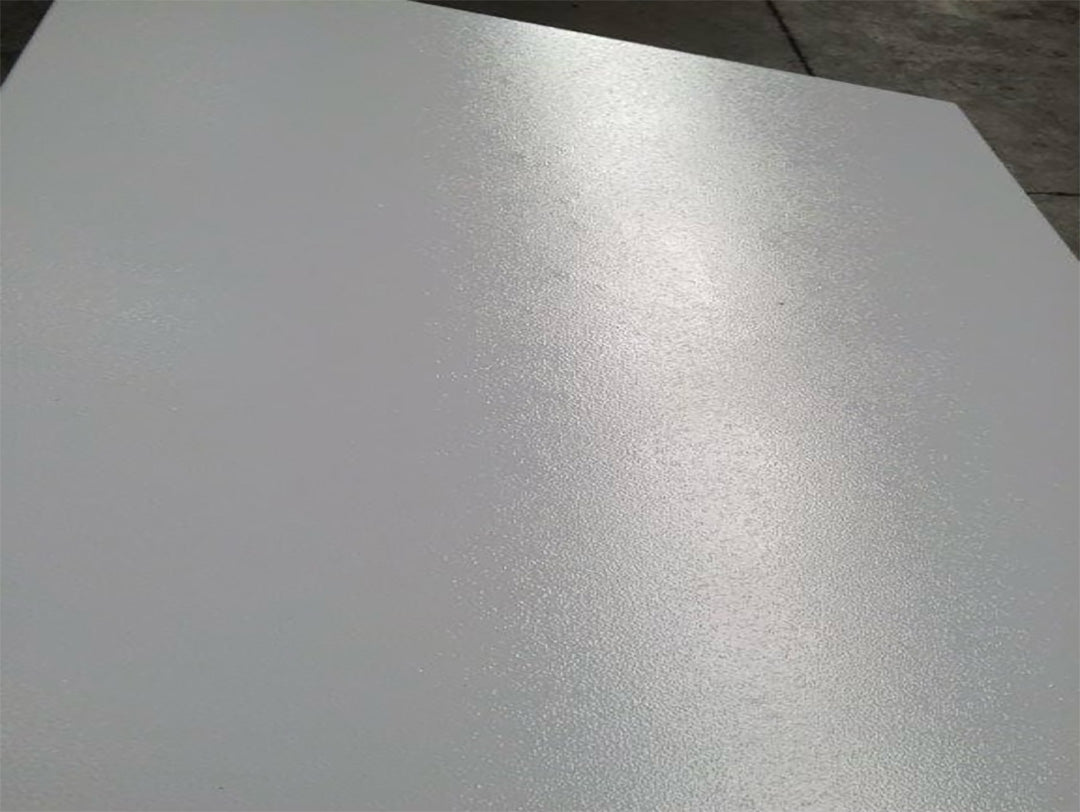

Clouding

Uneven light to dark or matt to glossy effect of the coating on the substrate

Blooming

Haze like film on the surface, which can be wiped off.

-

Solution

Ensure metal temperatures reach the recommended curing temperature. Whilst coatings will cure at reduced temperatures when given a longer cure, this may cause severe blooming. Do not leave products to cool in a box oven. Once the curing cycle is complete, open the oven doors and remove the work.