Coating Defects

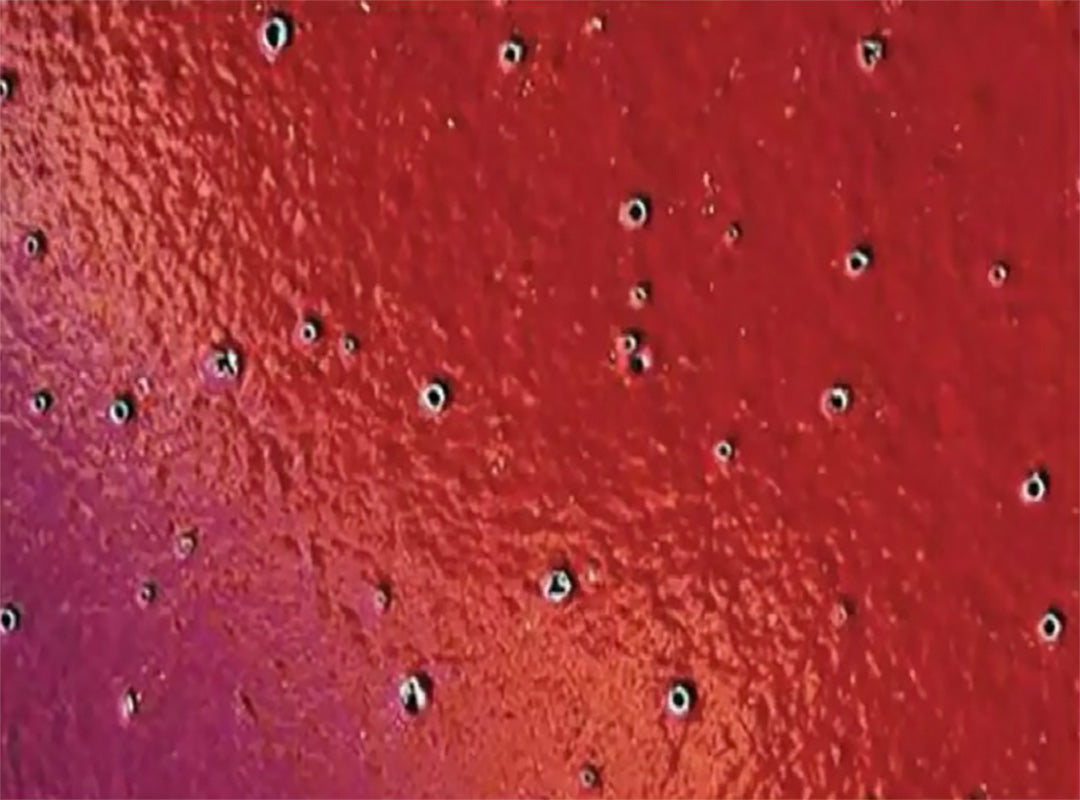

Craters

Areas in the coating surface where film thickness has been precipitously reduced, potentially to the substrate surface.

Craters

A blank area in the powder coat, which extends all the way to the substrate (diameter up to 2mm).

Pinholes

Very small craters, usually not extending down to the surface.

-

Solution

Adjust dry off oven temperature to ensure no moisture is on the part. Check powder for oil or moisture introduced in reclaim, from the air supply or the virgin powder. A thick film may cause out-gassing. Reduce the film thickness to enable the gas to escape through the surface during cure. Polyurethane powder coatings may emit a blocking agent. Excessively high cure temperatures may make lower polymeric components within the coating volatile. Note oven temperatures if pinholes form.